Our technology, explained

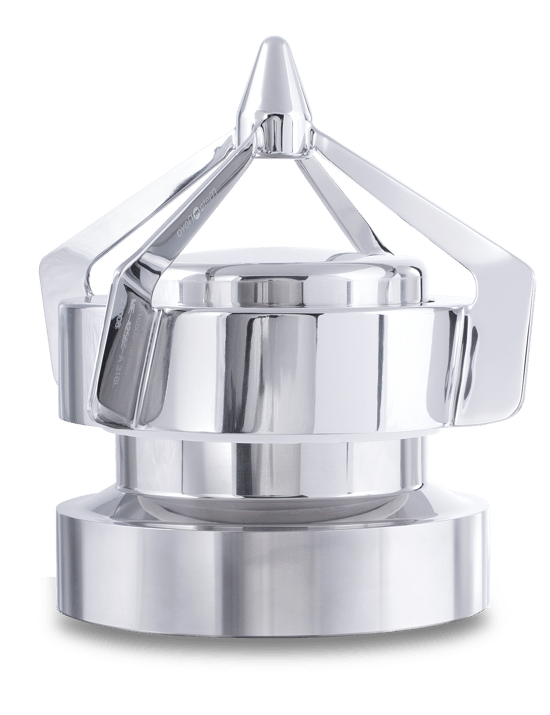

The Zero Gravity technology

The innovation replaces the horizontal thrust bearing with two repelling magnets. This minimizes the risk of damaged ceramics, which is common with traditional bearings.

The patented robust design provides a magnetic “cushion” that acts like a suspension during the installation of the mix head and transport of the vessel. The patented design provides extremely low wear and maintenance is kept to a minimum. The Zero Gravity Technology enables a very high level of aseptic design.

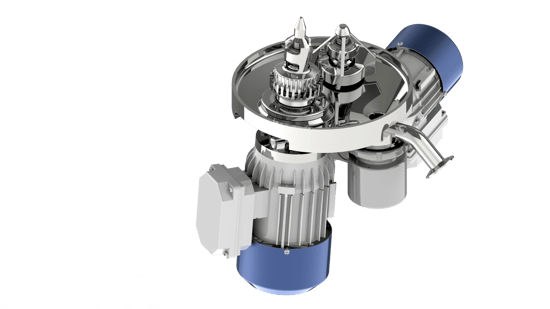

The Truelev technology

The Truelev Technology is the most advanced mixing technology available perfect for shear-sensitive applications such as mixing proteins minimizing the potential for shear damage.

By removing the mechanical friction of bearings and replacing it with a Mix Head free-floating on an active electromagnetic bearing, the technology has eliminated the risk of components potentially damaging the solution. This also enables maintenance-free mixing with a very low risk of breakage or wear.

.jpg?width=1600&name=DSC00278(1).jpg)